The Sweet Science Of Making Vitamin Gummies

Introduction

Making vitamin gummies at home can be a surprisingly simple and enjoyable process. For those looking to make their own vitamin-infused treats, this guide provides an accessible exploration into the science of vitamin gummy production. From selecting the right ingredients to the equipment needed, this article is a comprehensive guide to making the perfect vitamin gummies. With the right ingredients, equipment and steps, anyone can create delicious and nutritious vitamin gummies in the comfort of their own home.

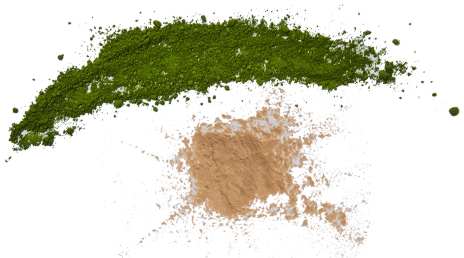

Ingredients

When it comes to producing vitamin gummies, there are several key ingredients that must be considered. First and foremost, the base for all gummies is sugar and starch. This base is then supplemented with other ingredients such as vitamins, flavorings, colors, and preservatives.

The sugar and starch base is typically sourced from corn syrup, sugar syrup, and maltodextrin. To this base, vitamins, such as vitamin A, vitamin B12, and vitamin C, are added to meet the daily vitamin needs of the person consuming the gummy. Flavorings are also added to give the gummy its distinct taste. Popular flavors include fruit, citrus, and caramel, though there are many more available to choose from. To give the gummy its distinct color, natural and artificial colorings are used. Lastly, Citric Acid helps extract pectin from fruit during gentle simmering and helps the gelling process, which will not take place unless the mixture is fairly acidic.

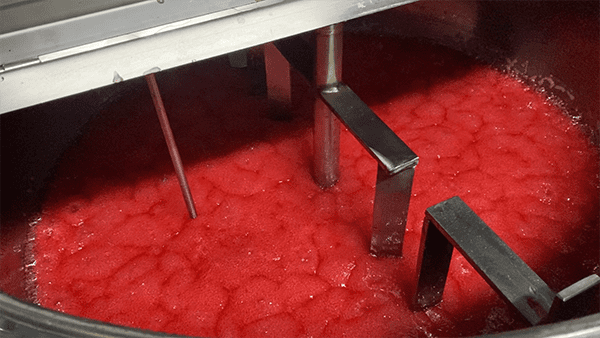

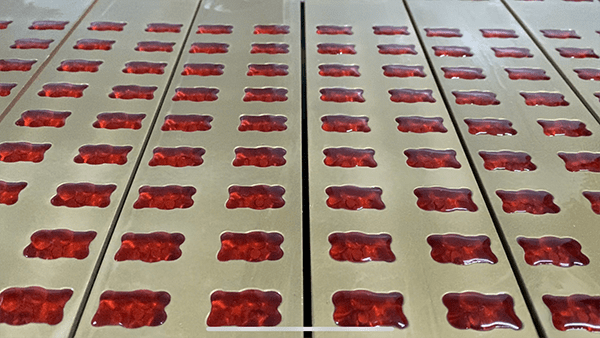

Once the necessary ingredients have been sourced, the gummy production process can begin. First, the sugar and starch base is melted and mixed with the selected vitamins, flavoring, and color. The mix is then cooled and molded into the desired shape and size.

The production process for vitamin gummies may seem complex, but with the proper ingredients and careful attention to the process, a delicious and nutritious gummy can be produced. With the right mixture of ingredients and precise production techniques, vitamin gummies can make for a tasty and healthy snack.

Vitamin and mineral supplements

Vitamin and mineral supplements in the form of gummies have become increasingly popular in recent years, due to their great tasting flavor and ease of ingestion. While it may appear to be a simple process, the production of gummy supplements involves a complex and precise science.

The first step in the process is to create a blend of vitamins and minerals which are contained within an aqueous solution. This blend is then cooked in order to dissolve the active ingredients, followed by the addition of binders such as gum Arabic and pectin. The desired texture and flavor must be carefully balanced in order to create a product that is both pleasant to consume and nutritionally complete.

Once the desired formula is achieved, the mixture is poured into a mold and allowed to cool and set. The cooling process is especially important as it helps to create the desired texture and strength of the gummy.

The unique blend of vitamins and minerals, and the precise process used to make gummies, means that they provide a convenient and delicious way to ensure that you're getting the nutrients your body needs. To ensure that you're taking the best possible vitamins and minerals, it's important to buy supplements from a reputable manufacturer that adheres to stringent quality standards.

Maltitol

Maltitol is a sugar alcohol commonly used in the production of vitamin gummies. This low-calorie sweetener can be used in either powdered or syrup form. As a sugar alcohol, maltitol has a slightly lower glycemic index than regular sugar and therefore has fewer calories, which helps to keep the gummies low in calories.

Maltitol is also beneficial for its ability to retain moisture and help form a gelatin-like consistency in the gummies. Maltitol has a higher boiling point than regular sugar, so it helps to keep the gummies from melting and becoming sticky. By using maltitol, gummy makers can create a more shelf-stable product.

In terms of taste, maltitol can be used to provide a sweet, sugary taste to gummies. While maltitol is not as sweet as regular sugar, it still provides a pleasing sweetness to the gummies that can mask any unpleasant aftertaste of the vitamins in the gummies.

Another advantage of using maltitol in the production of gummies is that it is relatively inexpensive compared to other sweeteners. This makes it a great choice for those looking to produce vitamin gummies on a budget.

In summary, maltitol is an ideal choice for the production of vitamin gummies. Its ability to retain moisture and provide a sweet, sugary taste can help to make the gummies both delicious and shelf-stable. Best of all, maltitol is relatively inexpensive, making it a great choice for those looking to make gummies on a budget.

Pectin

Pectin is a natural dietary fiber that is commonly used in the production of vitamin gummies and other confectionaries. It is derived from fruits, and when added to gummy mixtures, it acts as a natural binding agent, creating a smooth texture and firm consistency.

When making gummies, it is important to use the right type of pectin so that the final product has the desired texture and flavor. The most common types of pectin used in gummies are powdered pectin, liquid pectin, and high-methoxyl (HM) pectin. Powdered pectin is the easiest to work with, and produces a chewy, gummy consistency, which is ideal for gummies. Liquid pectin and HM pectin are more commonly used in jelly-type gummies, but can be used in other gummies as well.

In addition to providing the desired texture and flavor, pectin also helps to retain vitamins in the gummy product. This is because pectin can act as a protective barrier which helps to preserve the vitamins and other ingredients within the gummy.

Pectin can also be used to improve the shelf-life of gummies by helping to retain moisture. This helps to keep gummies soft, chewy, and delicious for longer.

Finally, pectin can also be used to add texture, flavor, and natural sweetness to gummies. It can be used in combination with other sweeteners, such as honey or agave, to create an even tastier gummy product.

In summary, pectin is an important ingredient in the process of making vitamin gummies. It is used to create the desired texture, flavor, and shelf-life, while also helping to preserve the vitamins and other ingredients in the gummy. As such, it is an invaluable ingredient in the production of vitamin gummies.

Citric Acid

Citric acid is a key ingredient in many gummy vitamin production recipes, providing a range of benefits that help create the perfect product. It is a naturally occurring organic acid found in citrus fruits, which give them their distinctive tart taste. Because it is a weak acid, it is safe to use in food products, although it can cause irritation if not used correctly.

The acidity of citric acid plays an important role in making gummies, as it is the key to controlling the texture of the finished product. Citric acid is used to add an acidic bite and control the overall pH level of the product, making it easier for the gummy to set and stay firm. Additionally, citric acid can be used to add sweetness or balance the other flavors in vitamins gummies, helping to create a more palatable product.

When using citric acid in gummy vitamin production, it is important to use the correct amount. Too much citric acid can make the gummies hard and sour, while too little can result in a gummy that is weak and crumbly. A good rule of thumb is to use half a teaspoon of citric acid per pound of puree or syrup used in the recipe. Once added, citric acid should be evenly distributed throughout the mixture, as this will ensure a consistent acidity level in the finished product.

Finally, citric acid is sometimes added to gummy molds before pouring the mixture in, as this can help the vitamins gummies remove from the mold more easily. When using this method, it's important to evenly apply the citric acid to the mold before adding the gummy mixture, as this will prevent sticking and help ensure a better finished product.

When used correctly, citric acid can be a great addition to any gummy vitamin production recipe, helping to control the texture, sweetness, and acidity of the finished product.

Equipment Needed for Making Gummies

The process of making vitamin gummies requires a few essential pieces of equipment. The most important piece of equipment is a gummy making machine. These machines are used to mix and heat the ingredients in order to form the gummies. They come in various sizes and can be used to produce large batches of gummies, or smaller individual portions.

In addition to a gummy making machine, a few other pieces of equipment will be needed. A double boiler is required to heat the ingredients, while a candy thermometer will be needed to measure the temperature of the mixture. Other important pieces of equipment include food coloring and molds to shape the gummies. These molds can come in a variety of shapes and sizes, such as bears, stars, and other interesting shapes.

For those wanting to further their production capabilities, a pasteurizer may also be purchased. This machine is used to keep the gummies from spoiling and to ensure their safety. It is especially important for businesses that are selling the gummies and need to guarantee their quality.

Finally, it is essential to have labels, packaging and storage materials. Labels are necessary for labeling the products, packaging materials such as bags or boxes for customers to take them away, and proper storage containers. This will help to keep the gummies fresh and safe for consumption, as well as helping to keep them organized.

With the right equipment, anyone can create tasty and healthy gummy vitamins. Following the proper steps and safety procedures is essential for a successful production of vitamin gummies. From selecting the ingredients to selecting the equipment, a great deal of time and effort is necessary to create top-notch products.

Instructions

The production of vitamin gummies can be a complicated but rewarding process if done properly. To help you get started, here are the steps for making vitamin-rich gummies.

1. Begin by selecting a recipe that fits your desired vitamin content. Make sure to pay attention to the proportion of ingredients and the type of vitamin you want in your gummies.

2. Prepare the gummy mixture by combining all the ingredients, such as pectin, sweeteners, vitamin powders, and other ingredients as called for in your recipe. You can find a variety of recipes available online or in cookbooks.

3. After the mixture is boiled, Citric Acid is added to help the gelling process.

4. Pour the mixture into candy molds and cool in the refrigerator for about an hour. This will help the mixture to set and form the gummy-like shapes.

5. Once the gummies have set, carefully remove them from the molds. Make sure your hands are dry and free of moisture, so that the gummies won't stick.

6. The final step is to coat the gummies in sugar or another type of coating powder. This will give them a sweet, sugary exterior and help to preserve them.

Vitamin gummies can be a great way to make sure you are getting your daily dose of essential vitamins. With the right recipe and care, you'll soon be enjoying delicious vitamin-rich gummies.

Tips for Making Gummies

Making vitamin gummies requires a great deal of knowledge and expertise in order to produce the best results. As with any production process, the details and techniques used in the production of vitamin gummies can dramatically affect the outcome of the product. Here are some tips to help you create the perfect vitamin gummies.

1. Choose the right ingredients - When making vitamin gummies, it is important to use the proper ingredients in order to produce the desired flavor and texture. Fruit-based gummies require a high-quality gelatin powder, while sugar-free and dairy-free gummies require a starch or agar-based thickener. Additionally, the right ratio of sweeteners, flavors, and colors should be chosen to achieve the desired outcome.

2. Select the right mold - Depending upon the type of gummy being made, selecting the right mold is a key factor in achieving the desired outcome. For example, gummy bears, worms, and shapes require a specific type of mold to ensure the proper size and texture.

3. Use the appropriate techniques - In order to create the ideal texture and consistency for vitamin gummies, it is important to use the right techniques. Temperature control, mixing speed, and other factors need to be considered in order to ensure the proper consistency.

4. Monitor quality control - Once the vitamin gummies have been produced, it is important to ensure that the desired quality standards have been achieved. In order to meet and maintain the desired quality standards, proper testing, packaging, and storage of the gummies must be done in order to preserve their freshness and texture.

Following these tips will help you produce the perfect vitamin gummies. With the right ingredients, mold, and techniques, you can create gummies that are both tasty and nutritious.